If you're getting ready to do some orbital welding, it's important that you take the time to properly prepare your pipe. There are a few key things that you need to do in order to make sure that your welding is successful. In this blog post, we'll discuss five tips for prepping piping for orbital welding. By following these tips, you'll be able to get your welds looking great and hold up under pressure!

Clean the interior and exterior of the pipe:

This is an important step in ensuring that your weld will be strong and free of contaminants. You'll need to use a pipe cleaning brush to remove any dirt, rust, or other debris from the pipe. Be sure to clean both the inside and outside of the pipe before you begin welding.

Remove scale from the pipe:

Scale can weaken your weld and make it more likely to fail. You'll need to use a pipe scaler to remove any scale that has built up on the pipe. Be sure to follow the manufacturer's instructions when using a pipe scaler.

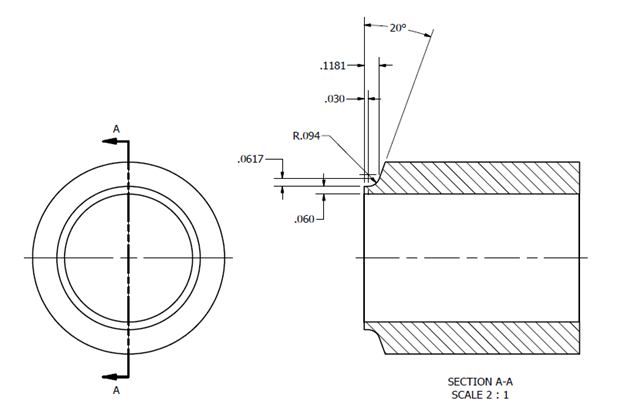

Prepare the pipe ends:

In order to get a good weld, it's important that you prepare the pipe ends. You'll need to use a pipe beveller to create a "J" bevel on the pipe ends. This will give you a nice, clean edge to weld on. The bevel should be clean and smooth, without any jagged edges. This will help to create a strong weld bead and minimize the risk of the weld cracking or failing.

Clean your orbital weld head and power supply:

Before you begin welding, it's important to clean your orbital weld head and power supply. This will help to prevent contamination of the weld and keep your equipment from heading to the shop too often. Make sure to brush out any debris with a soft bristle brush or microfiber rag for best results.

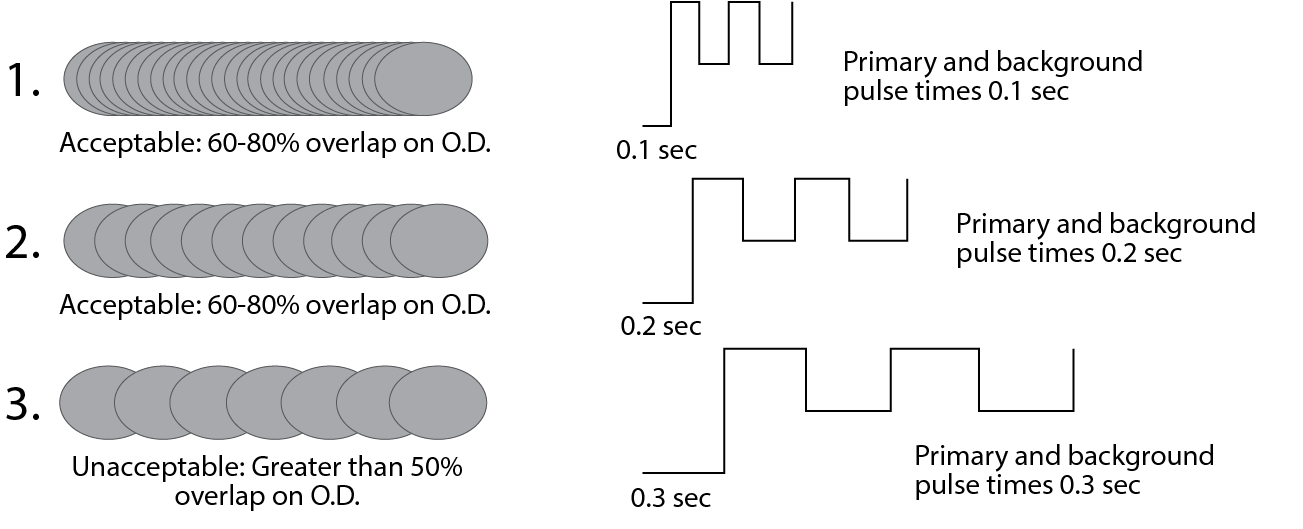

Check your welding parameters:

Once you've prepared your pipe and cleaned your equipment, it's time to check your welding parameters. You'll need to set the correct amperage, voltage, and travel speed for your welding process. If you're not sure how to do this, our team is available for training for your orbital welder (contact our Business Development team for more information).

By following these tips, you'll be able to prep your pipe for orbital welding like a pro!

Interested in learning more about our orbital welding lineup or taking a training course? Drop a line below and a member of our Business Development team will be with you within 24 hours!

Interested in learning more about our orbital welding lineup or taking a training course? Drop a line below and a member of our Business Development team will be with you within 24 hours!

Aug 15, 2022 9:49:49 AM

.png)

Comments