Pipe beveling joints play a crucial role in various industries, ensuring strong and efficient connections between pipes. In this blog, we will explore different types of pipe beveling joints and delve into their specific applications. By understanding the characteristics and advantages of each joint, industries can make informed decisions to achieve optimal results in their welding projects.

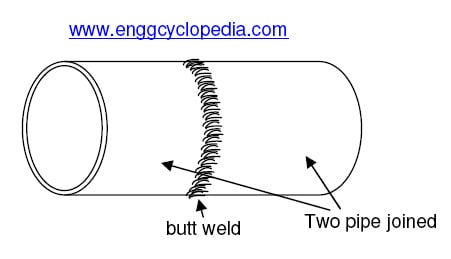

Butt Joint:

A butt joint is one of the most common types of pipe beveling joints, where two pipes are joined end-to-end. Its simplicity and ease of welding make it suitable for applications in construction, plumbing, and oil and gas industries. The even surface created by a butt joint ensures a seamless flow of fluids or gasses through the pipe system.

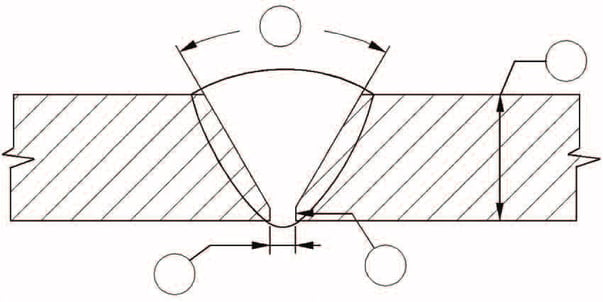

V-groove Joint:

The V-groove joint features a V-shaped groove on the pipe ends, allowing better penetration of the welding material. This joint is highly suitable for industries requiring strong and efficient connections, such as shipbuilding and structural steel fabrication. Its enhanced strength and weld quality make it ideal for critical applications.

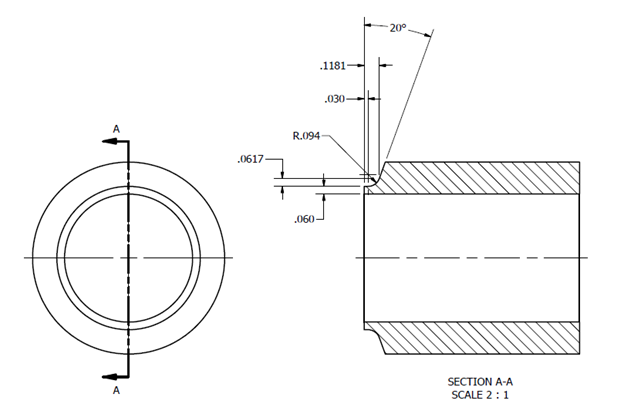

J-groove Joint (J-Prep):

A J-groove joint incorporates a J-shaped groove, providing a smooth interior surface that minimizes the accumulation of contaminants. Industries such as food and beverage processing and pharmaceuticals rely on J-groove joints for their hygienic requirements. These joints ensure the integrity of the piping system and facilitate easier cleaning and maintenance.

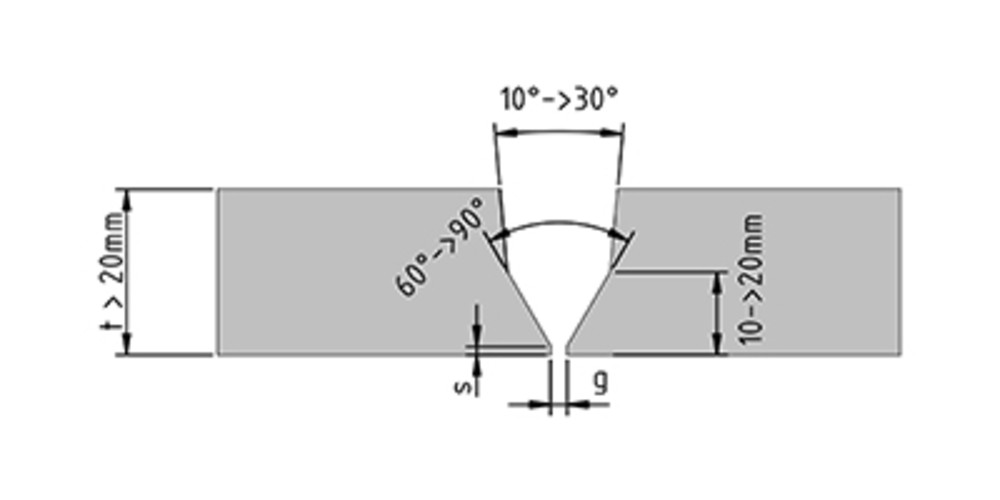

U-groove Joint:

U-groove joints are designed for situations where access for welding and inspection is limited. The U-shaped groove allows welders to reach difficult areas and ensure a secure connection. Industries involved in pipeline construction and maintenance often utilize U-groove joints to overcome space constraints and ensure the integrity of the pipelines.

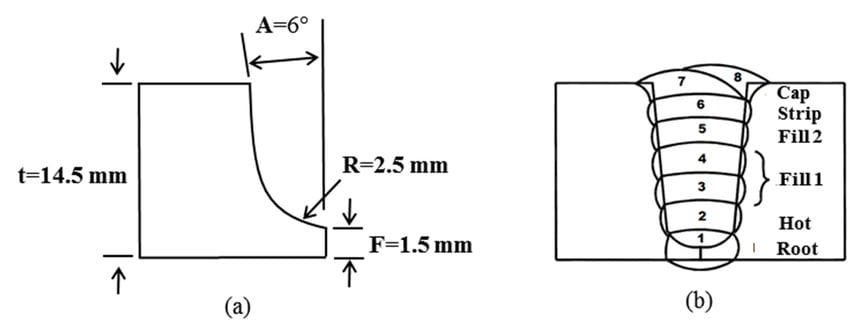

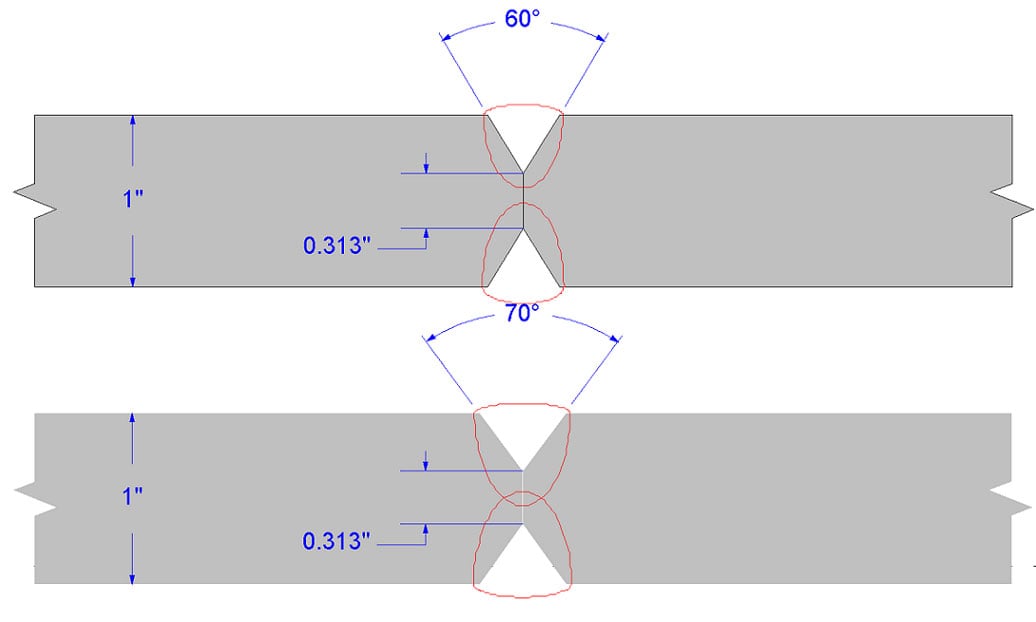

Double V-groove Joint:

Double V-groove joints provide exceptional strength and load-bearing capacity, making them ideal for applications requiring high-stress resistance. Industries involved in pressure vessel fabrication and heavy machinery manufacturing benefit from the superior joint strength and structural integrity offered by double V-groove joints.

Compound Bevel Joint:

A compound bevel joint combines multiple bevel angles, providing precise alignment and fit for specialized applications. Industries such as aerospace and automotive manufacturing rely on compound bevel joints to achieve the required geometries and ensure optimal performance of their components.

Understanding the differences between pipe beveling joints and their applications is crucial for successful welding projects. By selecting the appropriate joint for your specific requirements, you can ensure strong connections, efficient flow, and optimal performance in your piping systems. Whether it's a butt joint for simple installations or a compound bevel joint for intricate applications, choosing the right pipe beveling joint is essential for achieving superior welding results.

Jul 14, 2023 10:04:00 AM

-1.png?width=520&height=294&name=Untitled%20design%20(7)-1.png)

.png)

Comments