Boilers have a long lifetime and are in constant use. Their constant use causes the need for frequent repairs and maintenance during planned shutdowns in the fall and spring season. Working on these large vessels is an urgent and demanding task. This means that the boilermaker tools necessary for the job need to be durable, quick, and perform a variety of actions such as replace or repair broken pipes and flanges.

Boilermaker tools that may be needed include items such as cutting tools, beveling machines, alignment tools, and flange facers.

Cutting Tools

APS-438 Millhog Saw - Air Powered Pannel Saw

ESCO’s Millhog Saw can cut boiler panels, tube, pipe, tanks, sheets and cylindrical structures. This all-in-one saw cuts with ease and leaves no heat-affected-zone to fight in later stages of fabricating. With this tool, you can easily remove compromised areas of boiler tube for replacement. Use track, flex track and trolley accessories to make operation simple and safe.

COHOG - Clamshell Split Frame Machine

The COHOG quickly cuts and bevels heavy walled pipe in one operation without vibration or chatter. The Cohog’s unique design eliminates the complication associated with traditional O.D. mounted tube and pipe clamshells. The frame is made from the strongest aluminum obtainable and features self-squaring clamp legs that quickly align and secure the machine.

The tool mounts onto the O.D. of a piece of pipe and rotates around the piece, cutting and beveling till there is a smooth split. You are then able to replace or repair sections of the pipe.

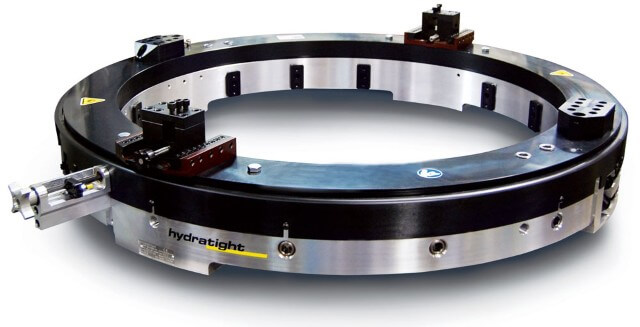

Enerpac Heavy Duty Clamshell - Clamshell Split Frame Machine

MIT also represents ENERPAC, a well-established manufacturer of machining and fabricating tools such as clamshells. Their heavy-duty clamshells come in a wide range of sizes and are ideal for large diameter heavy wall applications. The portable split frame machine is capable of pipe cutting, beveling, facing, I.D. boring and O.D. turning on a wide range of wall thicknesses. It comes in both pneumatic and hydraulic drive options.

Boiler Tube and Pipe Beveling Machines

MIT’s tube and pipe beveling machines come from a line of ESCO Tools called the Millhogs. ESCO Tool was the first equipment manufacturer to develop portable beveling equipment and to create a design that clamps the I.D. instead of the O.D. Millhog equipment is known for its high-quality bevels and is durable for intense use. Most Millhog equipment comes in battery-powered, electric, and pneumatic options.

Equipment Options:

These tools need bits specific to your chosen tool and application. Stock these consumable items on the job site and replace them as needed.

Flange Facer

Flange Hog 110 - Manual Flange Facer

Quickly recondition rusty and worn flange gasket seats to like-new conditions. This easy to operate flange-facing tool is perfect for re-facing raised-face and flat-faced flanges on-site or in a fabrication/repair shop. Set-up is easy and creates a precise finish in no time.

Tube Alignment Tool

Hog Tie - Tube Alignment Clamp

The Hog Tie boiler tube joint alignment tool speeds the welding process for boiler tube water wall panel replacement by quickly and accurately aligning new boiler tube ends with existing tubes in preparation for creating welded tube joints. The open windows on both sides of the Hog Tie allow efficient tack welding. Accurate tube alignment helps to make a better-welded tube joint and reduces the risk of tube joint failure due to inaccurate alignment. This saves valuable time and money on costly boiler shut-down and re-work.

Make the most out of your planned outage by having the boilermaker tools you need on hand. Replace and upgrade any old equipment or processes that can be solved with these tools to increase efficiency.

Our emergency rental fleet is conveniently located in the Midwest and can save you valuable time if any equipment goes down on the job. Contact us to learn more.

Tags:

Outages, Pipe Beveling, Boiler Tools, Plant Shutdowns, Boilermaker tools, Boiler Tube, Beveling Machines, Milling MotorsSep 30, 2020 12:00:00 AM

.png)

Comments