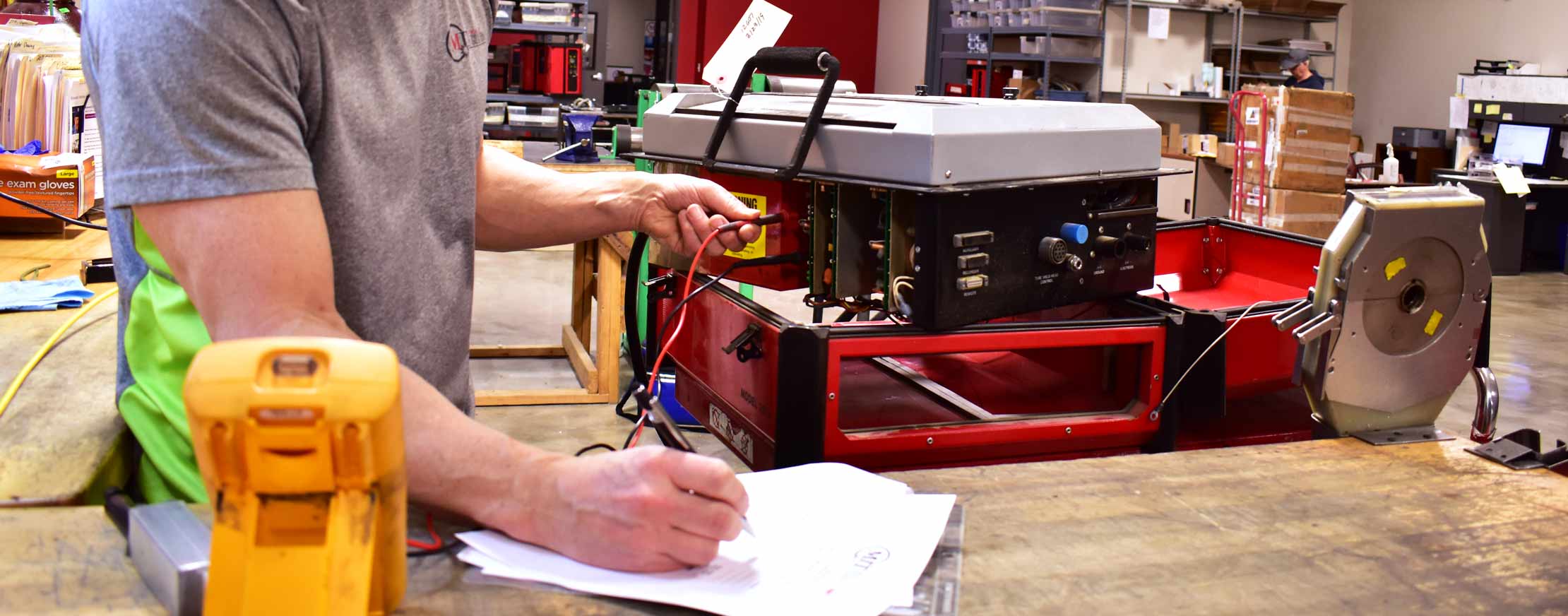

Due to the COVID-19 pandemic, many projects have been slowed, entirely shut down or restructured due to paralyzing restrictions.We encourage customers to make sure their orbital welding equipment is prepared to meet project demands once restrictions are lifted. Our factory-certified repair team can inspect and calibrate your orbital welding power source so that it is ready to weld once your job is back on track.

MIT always encourages you to calibrate your power supply annually if your machine sees regular use. Power supplies have the tendency to drift out of calibration over time, causing the machine to produce inconsistent voltage from weld to weld. Our orbital welding repair team follows detailed guidelines to ensure the machine meets the recommended factory specifications after calibration completion.

During the calibration, our service team estimates and completes general repairs of the machine as well, including replacement of the batram, batteries and other parts if needed. Repairs and general maintenance can prevent equipment failure, saving valuable time on a project.

Some companies require current orbital welding power source calibration certifications on machines that are being used at their facilities. Our calibration certificates help ensure that standard requirements are being met for inspection.

With over 25 years of experience, MIT has the knowledge and resources to evaluate your Magnatech or Arc Machines Inc equipment and determine the necessary steps to get your team up and running. Our factory-trained technicians use service equipment that is certified, calibrated, cleaned and tested on a regular basis to ensure maximum efficiency when inspecting your equipment. MIT is committed to providing you with quality service and solutions.

Contact us at (417)485-4575 to speak to our team about power source calibration or orbital welding repair.

May 5, 2020 12:00:00 AM

.png)

Comments