Not every orbital weld head is the same - there are two types of motors used depending on the brand and type of weld head. These internal motors provide feedback to the system’s power supply in order to control the weld head’s speed and/or position.

Tachometer Motors

Tachometer motors can be found most frequently. A simple sensor, called a tachometer, is mounted on the rotating shaft of the motor. It is essentially a small generator made of coiled wire and a magnet. The tachometer generates a voltage, which is proportional to motor speed. The voltage information is used to maintain a constant programmed speed. However, it is impossible to manufacture the tachometer sensor to be identical from motor to motor. With a tachometer motor, weld head calibration will need to be performed at the beginning of each shift or every time a different weld head is connected.

Encoder Motors

The other option is using a weld head with an encoder motor. A sensor called an encoder is mounted on the rotating motor shaft. These encoders use more sophisticated electrical components to create digital pulses as the motor runs. The digital pulses are relayed easily to microprocessor controls to maintain a constant speed. Because of their design, all encoders of a certain model put out identical numbers of pulses per revolution, which can never vary. There is no need for calibration, as there can be no changes in the number of pulses.

Advantages & Disadvantages

One drawback of tachometer technology is that the variability of these sensors requires calibration, even when new. Its reading of the weld head may not take certain variations into account, leading to feedback that is less precise than that of encoder motors. Other variables that can affect output are wear and motor temperature. Tachometer motors are also more electrically “noisy” and are susceptible to outside influence.

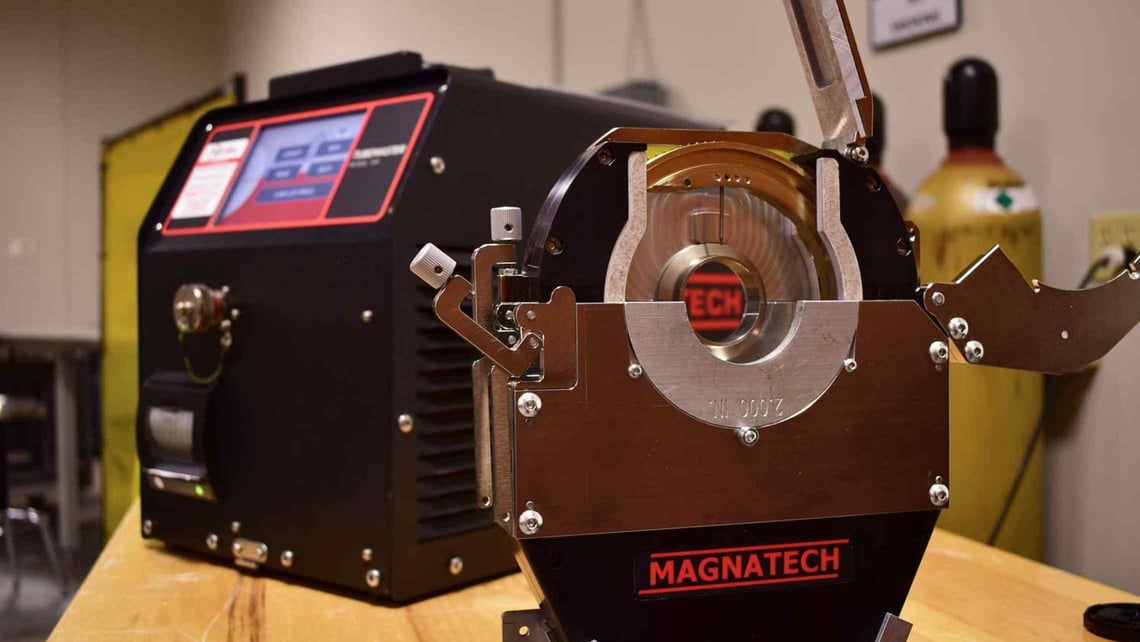

Magnatech uses encoder motors for most of their weld heads. This technology provides more accurate speed regulation, eliminating periodic calibration - saving you time and simplifying your orbital welding process. An added benefit is that if a motor stops rotating, the pulses immediately stop, and power to the motor can be immediately turned off. If a jam occurs, the immediate response means no damage will be done. To restart, press the reset button located on the back of the orbital power supply.

Alternatively, the response of a tachometer motor is too slow to prevent damage. To combat this issue, manufacturers use a mechanical safeguard. This safeguard is a sacrificial part designed to break when the motor is put under an excessive load. Safeguard breakage requires your equipment to be sent in for repair.

If both types of motors are working perfectly, there is very little disparity between the quality of welds. The main differences lie in the process of providing feedback to the power supply in order to control the speed of the weld head, the need or lack thereof for frequent calibration, and the damage control speed.

Aug 3, 2020 12:00:00 AM

.jpg?width=520&height=294&name=Email%20Infographics%20(2000%20%C3%97%20800%20px).jpg)

.png)

Comments