Orbital cutters can quickly cut both tube or thin walled pipe in preparation for an orbital weld. MIT has several orbital saw blade options for your application - including both tube and pipe saw blades.

Why Tube and Pipe Saw Blades Are Different

We know tube and pipe are not the same, but why is there a difference in their blades? Wouldn’t it make sense to save money and increase efficiency by using the same saw blade to cut both?

We can start to understand why the blades are different when we focus on the tube and pipe itself. Pipe normally has a thicker wall than tube, meaning there is more material to remove when making a cut. The more teeth a blade has, the finer each tooth will be. This means that each time a tooth engages with material for a cut, it takes out a relatively small chunk of the material. Inversely, a blade with fewer teeth will be coarser, meaning each tooth will remove more material than a fine tooth.

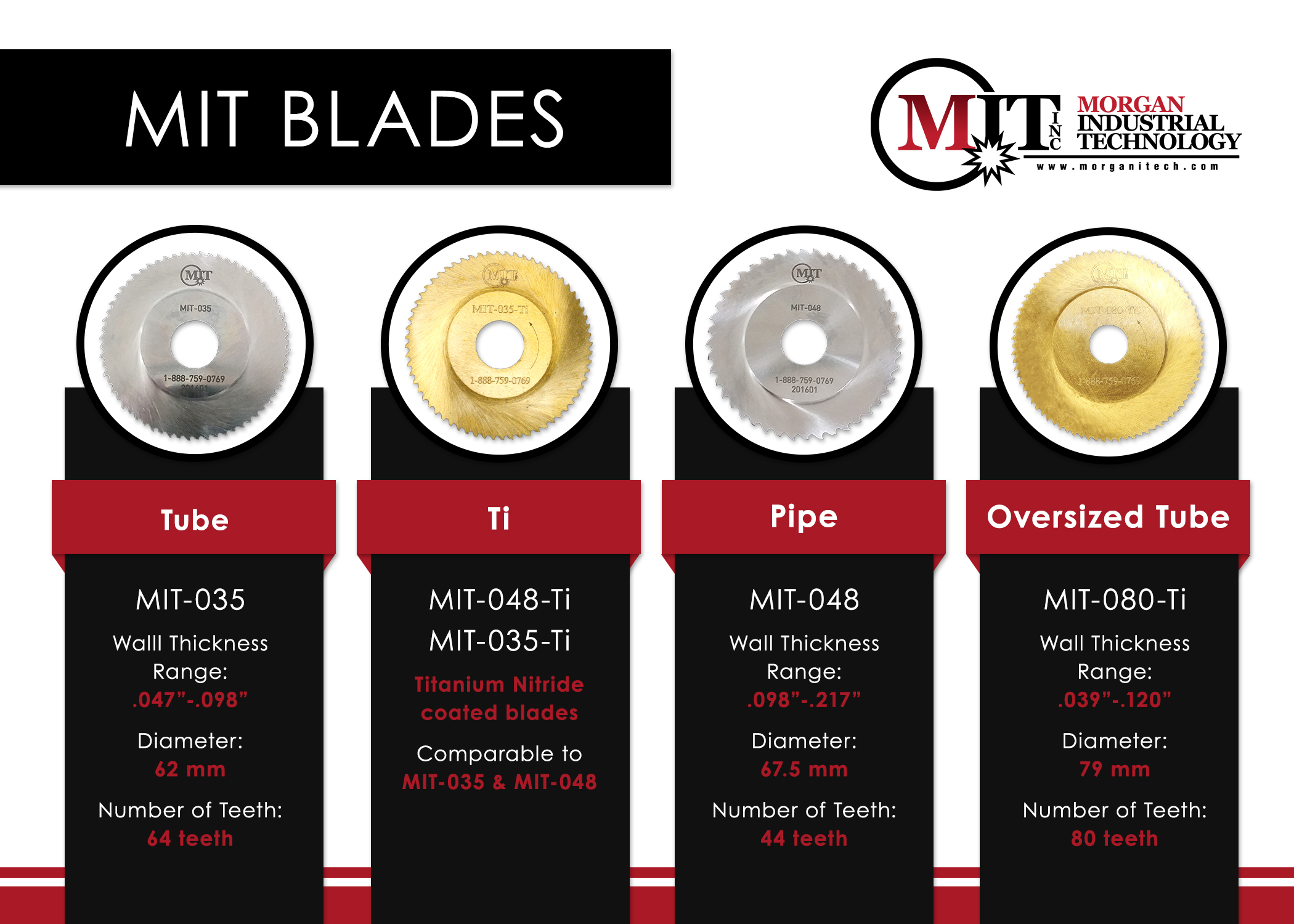

When cutting pipe, you want to use a blade that can remove more material per tooth. However, while cutting tube, it is important to make as clean and precise a cut as possible. This is accomplished by having more teeth hit the material per rotation of the blade. That is why our standard pipe blades have 44 teeth while our standard tube blades have 64 teeth.

Think of it this way. To cut down a large tree, would you rather use a small hatchet or a big axe? Obviously, the axe would be the tool of choice because more progress would be made with each swing. However, if you are trying to make hand-held wood carvings, you would want to use something much smaller and precise, like a pocketknife. This may be an extreme example, but it gets the point across.

So, what would happen if you used a tube blade on pipe or vice versa? The immediate result of using a tube blade to cut pipe would be substantially decreasing the life of the tube blade. It may be able to make the cut three or four times, but it would not take much time before the blade needs replacing. On the flip side, if a pipe blade is used to cut tube, the cut quality would be much worse. The results would not be as clean as if done by the correct blade. More that the usual amount of facing before a weld could occur.

Cutting on Different Material

It is also important to consider the material before performing any cuts. The two most common types of material our customers deal with are carbon steel and stainless steel. Stainless is a harder material and therefore can wear out a blade faster than carbon, a softer material.

It may sound counterintuitive, but it's optimal to cut stainless steel slowly. Heat is the enemy of blade life, and heat is produced by friction. The faster the revolution of the blade, the more friction and heat is produced. The slower you cut, the cooler the blade. This practice helps increase blade longevity.

Why Use Ti or Oversized Blades

Besides our traditional tube and pipe orbital saw blades, we also sell titanium nitride (Ti) coated blades. Titanium nitride is a material used to coat blades and bits to increase the life and hardness of the blades. They appear gold in color and hold up well under heat. They are an inexpensive blade option that doesn’t lose any cutting quality.

Oversized blades are another option MIT offers. Oversized blades are used to extend the saw’s range. For instance, if your saw’s size range can cut 1.5” to 4” tube, you can use an oversized blade to cut 1” tube.

Have questions about blades in your specific tube or pipe application? Contact your sales representative at 417-485-4575 and place an order of premium saw blades today.

Aug 20, 2020 12:00:00 AM

.png)

Comments