The perfect pipe does not exist - no matter what the manufacturer tells you.

The smallest variations in length, wall thickness, and ovality make this impossible. While these imperfections can be minimized by finding the best manufacturer to fit your tolerances, they can never be prevented or avoided. These imperfections often come to light during the fit-up - causing misalignment, sometimes known as hi-lo. While the elusive “perfect fit-up” does not exist, there are steps you can take to create the best fit-up possible. This is especially important for applications using an automated process such as orbital welding.

Why is Misalignment or Hi-Lo Important?

According to OMS, misalignment or Hi-Lo is the difference between the internal and/or external heights of two pipes. Poor alignment causes a weaker weld that is less able to cope under high fatigue conditions.

Most commonly this misalignment occurs when the fittings being welded to the tubes are made to different dimensional tolerances. If the tube or fitting is out-of-round, if the OD or wall thicknesses differ, this will produce some misalignment. Misalignment results in a ridge on the inside of the weld that can interfere with the drainage of the piping system. Such liquid accumulation would promote corrosion and contamination due to bacterial growth.

Misalignment is more common in larger pipe sizes – typically 6 inches and above. The larger the pipe gets, the more likely it is to be out of round or to become warped during storage or transit.

Hi-Low Tolerances - When Does Misalignment Become a Problem?

Tolerances differ between tube and pipe. Misalignment is sometimes a problem when people try to weld pipe fittings, which have loose tolerances, to tubing which has tighter tolerances.

Tube

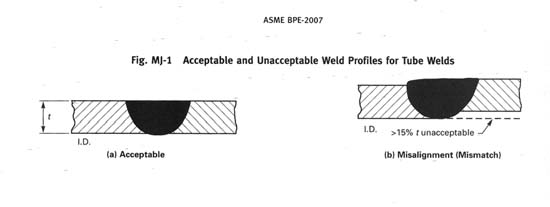

To meet the visual requirements of the BPE Materials Joining Part illustrated here, the misalignment (mismatch) must be less than 15%. Deviances greater than 15% are unaccepted.

Pipe

A rule of thumb when it comes to pipe is that you cannot have more than half the wall thickness misaligned. It’s up to the onsite code or quality control manager as to what the acceptable tolerances are. There is too much variance in applications as it pertains to material, wall thickness, welding process, and more. There isn’t a set pipe hi-lo tolerance because of this.

How Do I Combat Pipe Misalignment?

When it comes to misalignment, there isn’t one quick fix. Different applications call for different solutions, and some joints are beyond aligning. While there isn’t a quick fix, there are a few processes that can get your joint weld ready.

Beveling

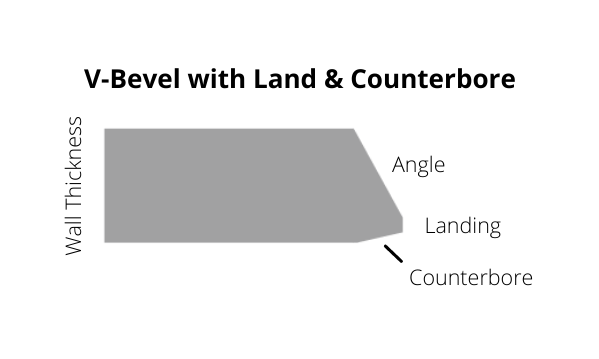

To alleviate hi-lo in a pipe joint, beveling is a common solution. Beveling is the process of removing material from the tube or pipe end. This is primarily done by counterboring. By removing material through a V-bevel, J-bevel, Compound Bevel, Face, or Counterbore, you can create a landing to align for a better fit-up. This is especially important while using automated welding processes such as orbital welding. Morgan Industrial Technology uses ESCO Tool pipe beveling equipment for weld preparation.

Orbital Welding with an Open Head

Open weld heads can adjust the arc gap as needed through automatic gap control, also known as AGC or AVC. Some models offer a manual arc length adjustment control. With fusion welding, the tungsten is a set distance from the joint. With an open weld head, a skilled operator can adjust the distance between the and the weld joint to account for out-of-roundness and the machine will automatically keep that distance until it is changed again. The operator of the wire feed welder watches the weld puddle and adjusts the weld parameters as needed.

Using Alignment Tools

Alignment tools can be mounted to the application to align and even reform for a better fit-up.

- Tig Tack Clamps are mounted to the joint for tacking before a weld.

- Mathey Dearman has a variety of alignment and reforming clamps. Cage clamps align pipe while chain clamps exert pressure on the high points of the mating pipe, eliminating hi-lo as pipe and fittings are aligned.

- In power plants, the ESCO Hog-Tie can align boiler tubes

Oct 28, 2021 2:46:40 PM

-1.png?width=520&height=294&name=Untitled%20design%20(7)-1.png)

.png)

Comments