You may have heard a tube facing tool mentioned as a suggested preparation tool if you are considering orbital tube welding. So, what is a tube facer used for?

The basic need for a facing tool is to square up stainless steel tube or pipe ends. A tube facer rotates 360 degrees around the tube or pipe end while shaving or “squaring” it of any burrs or imperfection after being cut. Using this step after an orbital saw or saw vise makes fit-up easy, accurate, and repeatable.

Why is tube facing important for my application?

The tube or pipe fit up has a direct impact on the quality of an orbital weld. Burrs can cause uneven blemishes in the weld.

In critical applications, these imperfect sanitary welds fail. This is due to the dangers of bacteria build up contaminating the product running through the tube or pipe system OR because the integrity of the weld is compromised.

What facing tool options does MIT have?

Morgan Industrial Technology represents T+C, a trusted facing tool manufacturer. Their products range from 1/8” to 6” pipe (6.625” OD).

Check out our tube facing tools here.

How much material do I need to take off for my tube end to be square?

You do not need to shave off much material - just a couple of revolutions with a facing tool will suffice. The shavings or “ribbons” should be thin and pliable. These tools are specifically designed for small, precision squaring.

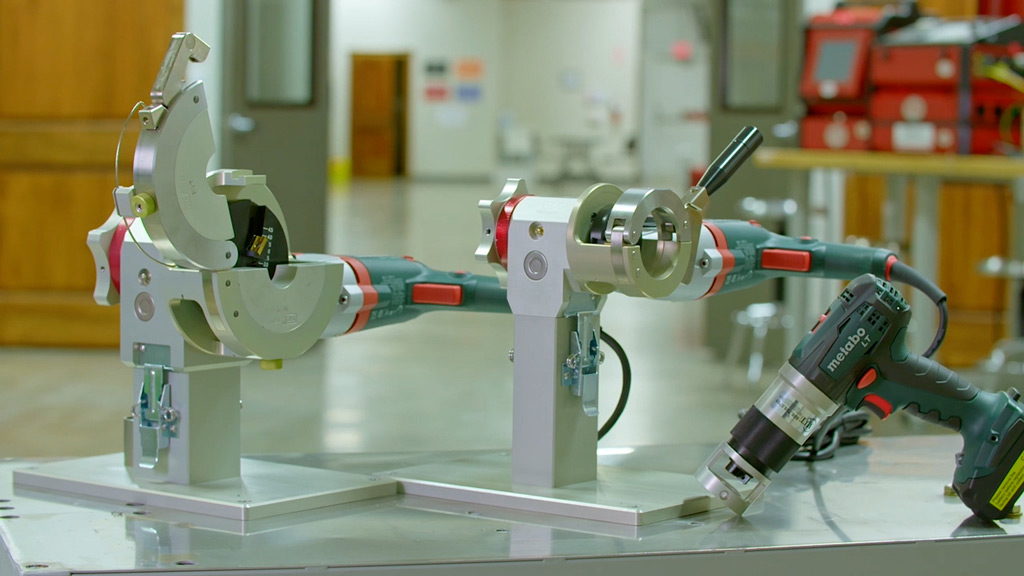

How do I work a tube facer?

Though all tube facing equipment is slightly different, they function quite similarly. The piece of material is placed in the facing tool and clamped. The clamp must not be set too tightly so that the piece is not in danger of becoming warped. The motor is then turned on and the facing bit rotates at the speed set by the user. The rotating facing bit can then be moved in and out to engage and disengage with the piece. On T+C tools, this action is performed with the back knob. The operation is completely tool free.

How many faces can I perform on a single facing bit?

Long story short - it depends on the application. A number of factors influence your bit life, including material, wall thickness, speed, and more. You will get more faces per bit by adjusting it to use all edges of the bit. Additionally, T+C bits are double-sided, meaning that you can make twice the cuts compared to other facing tool brands.

Interested in learning more? Check out the tube facing tools we carry and contact us for more information.

Apr 20, 2021 12:00:00 AM

.png?width=520&height=294&name=Arc%20Gap%20Cover%20Image%20(7).png)

.png?width=520&height=294&name=Arc%20Gap%20Cover%20Image%20(3).png)

.png)

Comments