Orbital Weld Heads: Open or Closed?

There is a lot of variation when it comes to orbital welding, from custom schedule developments and collet sizes to the speed and arc gap. Orbital Welding can be incredibly complex. One of the key components to a successful weld is the choice of weld head. There are 2 main types of weld heads in orbital: Open and Closed. These heads follow the core concepts of orbital but have incredibly varied functions when it comes to creating welds. Open heads, like Magnatech's D-head are O.D.-mounted, argon fed, welding tools that blow traditional TIG welding out of the water when it comes to consistency and reliability in their welds. However, on small welds (< 3") they are equivalent to using a sledgehammer to push a thumbtack into a wall. The smaller closed heads create great welds for tube and pipe while shielding the workpiece from atmospheric gases. Learn more about the differences and which one you should use below.

What is Orbital Welding

Orbital welding is an automated welding process that creates consistent and repeatable welds. Unlike a typical TIG welding machine, orbital welders use a power supply and a motorized weld head to rotate around the workpiece creating a weld bead (hence the name orbital). The closed weld head prevents contamination and oxidation by enclosing the gas and tungsten electrode and limiting atmospheric gases, which typically cause porosity and other defects in welds. The process has been shown to produce higher quality welds while also requiring less operator input than traditional manual TIG welding. The standards of quality in aerospace, pharmaceutical, and high purity welders can't rely on their eyes to detect defects anymore. Instead, they need high-quality equipment like AMI, Magnatech’s, Axxair’s machines to ensure every weld is perfect every time.

What is a Closed Weld Head

A closed head weld head is any head that has encloses around the workpiece and tungsten electrode. These are most often used in sanitary and non-sanitary tube applications as the work pieces have a size limit of 1/4" - 6 ". The workpieces are aligned with the electrode and clamped into place. Argon or Helium is pumped into the weld head to prevent weld splatter and the computer then begins a purge process. When the automated welding program runs, the electrode orbits around the tube or pipe and creates a seamless weld. This type of welding equipment is becoming increasingly popular in the market, as it offers many benefits to the user. The enclosed environment protects against atmospheric contamination as well as makes it possible to use non-consumable tungsten electrodes. Some examples of a closed weld head are the AMI 8-4000, Magnatech's M-500, and the Axxair SATFX-52.

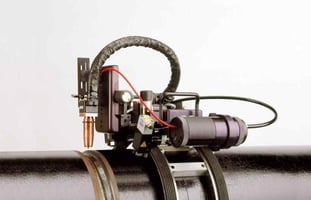

How an Open Weld Head Works

Open weld held is fundamentally similar in terms of capabilities but encompasses a unique niche in orbital welding. Where closed heads excel in tight spaces, on bench welding and in creating extremely precise welds, open heads make welding large diameters OD's easier with more consistency. Open weld heads mount to the OD of the tube or pipe and rotate on a track. Argon is pumped in higher quantities near the electrode to compensate for the lack of shielding. AMI, Axxair, and Magnatech all take different approaches with the execution of their Open weld heads, but the Magnatech D-Head, Axxair SATO Series, and AMI Model 95 help pipe fitters and welders make perfect welds with little intervention.

Which Should You Choose? Open Head or Closed Head?

Choosing between an open or closed head is completely up to your application and use case. If you're welding large diameter tube or pipe or have a wall thickness at or greater than .150", a closed weld head won't get the job done. The amount of heat produced by these welds could melt the interior components of the head or cause punctures, burnout, or tungsten-inclusion on the finished weld.

For most tube and pipe applications, a closed weld head work will work great! The weld head shields from atmospheric gases and makes clean welds that are great for aerospace, pharmaceutical, automotive, and dairy.

Learn something new? Have a different opinion? Leave a comment below.

Oct 27, 2022 11:09:29 AM

.jpg?width=520&height=294&name=Email%20Infographics%20(2000%20%C3%97%20800%20px).jpg)

.png)

Comments