Is orbital welding right for your tube or pipe application? Keep reading to find out.

In this guide, you will learn the essentials when it comes to orbital welding. From applications and industries to weld preparations and programming, MIT will share all you need to know about orbital welding.

Shortcuts

Orbital Welding Applications & Industries

How to Orbital Weld: the Orbital Welding Process

What is Orbital Welding

Orbital welding is the automatic or mechanized welding of tubes or pipe in place with an electrode rotating (or orbiting) 360 degrees around the workpiece. Orbital welding can be conducted on tube or pipe with the addition of filler material or as a fusion process.

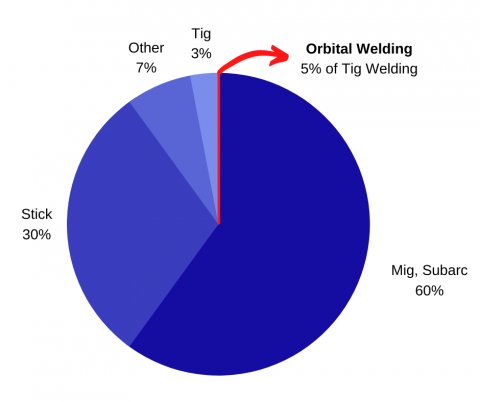

In the 1950s, orbital welding was developed by the aerospace industry to replace compression fittings and manual welds. This type of welding falls under TIG (Tungsten Inert Gas) welding. As you can see in the graphic below, TIG constitutes for only 3% of welding worldwide. Then, only about 5% of TIG welding is comprised of orbital TIG welding.

Though orbital welding represents only a small percentage of applications, its creation has been vital to the ever-growing standards and success of many industries.

Don't have time for the full article? Watch our introductory orbital welding video:

Benefits of Orbital Welding

Manual welding can be unreliable, and workloads can often become greater than even the most skilled welders can handle. With an orbital welding system, uniform welds can be created quickly with a minimized risk of human error.

The orbital welding process is designed to produce welds that meet ASME BPE acceptance criteria. Consistent bead size and full penetration create smooth surfaces that prevent microbiological growth and possible contamination of the product. This is especially beneficial in critical applications such as in the pharmaceutical or food and beverage industries.

Orbital Welding guarantees:

- Increased Speed and Process Efficiency

- Weld Quality - Accuracy and Consistency

- Weld Repeatability

- Weld Cleanliness

- Versatility for Unique Applications - such as a piece unable to be rotated, that has poor visibility, or is in a hard to reach area

- Weld Documentation and History

Orbital Welding Prevents:

- Poor Penetration

- Lack of Fusion

- Poor Purging Techniques

Orbital Welding Applications and Industries

Any tube or pipe with material running through it has the potential of being welded with an orbital welder.

Applications

- Sanitary Tubing

- Tube to Tube

- Tube to Fitting

- Fitting to Fitting

- Pipe

- Pipe to Pipe

- Pipe to Fitting

- Exotic Alloy Application

- Tube to Tube Sheet

- Overlay Applications

Industries

- Semiconductor

- Biotechnology

- Pharmaceutical

- Cosmetic

- Food & Dairy Processing

- Breweries & Wineries

- Electronics

- Chemical

- Aerospace

- Nuclear Piping

Orbital Welding Machines

An orbital welding system is composed of three pieces: the power supply, water cooler, and weld head.

Power Supply

The power supply, also known as a power source or controller, is where weld programming is conducted. These power supplies are microprocessor-based and control all the weld parameters. It communicates weld speed, amperage, pulse time, purge time, and more to the weld head. Power supplies with wire feed capabilities have additional controls. As a minimum, this would include wire feed speed and provisions to advance or retract the wire. The power supply also documents welds, stores programs for future use, and features a printer for documentation purposes after each weld. The system weld schedules help produce consistent and repeatable welds.

Water Cooler

The water cooler is an important component of the orbital welding system. It interconnects to the weld head and holds cooling fluid. We recommend a low conductivity coolant/antifreeze jug of glycol. Utilizing a pump, the water cooler flows the coolant through the weld head coolant lines and into the weld head. This allows the weld head to run at 100% duty cycle and prevents the inner components from overheating during the weld.

Orbital Weld Head

Orbital weld heads connect to the power supply and water cooler through a series of cable connections. There are two options when it comes to weld heads: enclosed heads and open weld heads.

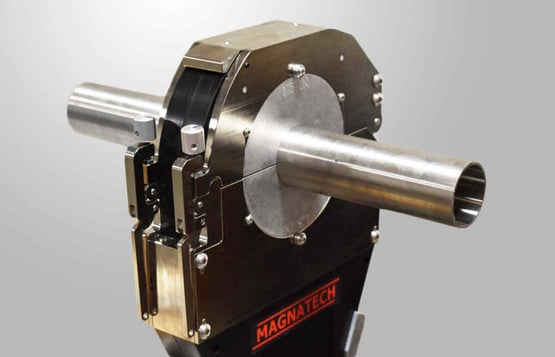

Orbital Tube Welding - Enclosed Weld Heads

Enclosed weld heads are often referred to as closed or fusion weld heads. They are closed, as the name suggests, creating an inert atmosphere chamber that surrounds the weld joint. They provide a continuous shield with inert gas flowing for the entire weld joint during pre-purge, the weld sequence, and post purge which allows cooling of the weldment before exposing it to the atmosphere. This encapsulated environment helps to create fusion welds with a decreased risk for blemishes or other imperfections. This is particularly important for the sanitary welding of processing lines in industries such as pharmaceuticals, food, beverage, and more.

No welding helmet is needed while conducting a weld. This type of weld head is typically used for orbital tube welding but can be used on thin-walled pipe. With an enclosed weld head the tubing and/or components, such as fittings, are held in position using tube clamp inserts or collets with the exact tube diameter that are installed on both sides of the weld head. The weld head rotor holds the tungsten electrode in place and is lined up to the joint. An arc is struck and the tungsten orbits around the tube or pipe, creating a fusion weld. Once the START button is pushed, the entire process is completely automatic.

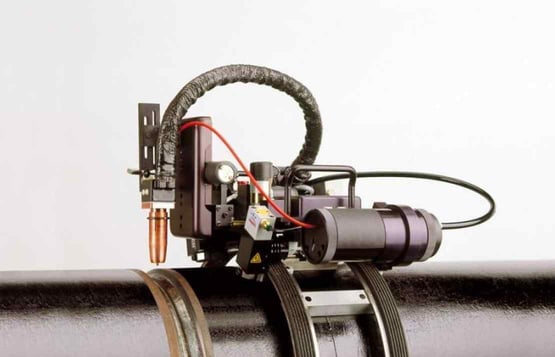

ORBITAL Pipe Welding - Open Weld Heads

These weld heads are most often utilized for pipe welding applications where filler wire is required, and multiple passes are required to complete the weld. There are two styles of weld heads offered in the open face design for pipe welding.

- The clamping style head uses a vise clamping system to mount to the workpiece

- The low profile or guide ring style uses a tracking system that mounts to the workpiece and attaches to the track

With these open frame heads, the shield gas is limited to the electrode and the weld pool directly beneath the electrode. The resulting weld has considerably more heat tint discoloration on the outside diameter (O.D.) surface than with an enclosed orbital head.

For an open frame head, the joint components must be tack welded in place or a bridge clamp used. A clamp on one side of the head holds the tube or pipe. The head must be properly aligned with respect to the weld joint and the wire angle and wire distance from the joint set. Orbital welding with wire feed is not fully automatic. Some adjustments such as torch steering to track the joint or adjustment to arc gap may be required. This takes considerably more operator skill than autogenous welding.

Orbital Welder Size Limits

When it comes to O.D., you can orbital fusion weld from a minimum of .125" (1/8”) to a maximum of 6”. Typically, sanitary tube is never larger than 6”, but there are always exceptions. Once you get into those larger sizes, it’s important to realize the fit-up usually isn’t completely square – there will be some high low action due to the oblong shape of the pipes used, making fusion welding difficult and filler wire ideal.

Our baseline maximum wall thickness for fusion welding is .120”.

As always, the maximum depends on the application. Larger sizes can be welded, but the thicker the wall, the more you will start to see concavity. We have had customers successful with thicknesses up to .187” wall thickness. They achieved full penetration and were welded in the vertical position to minimize concavity. Note that the application in reference did not need a completely flush weld on the inside.

You can orbital pipe weld from a minimum of .5" O.D. with no maximum. The clamping style usually ranges from .5” to around 6.625”. The low profile, or track ring guided style heads, can be used .5” and beyond. The guide rings/tracks can be bought in basic tube and pipe sizes in sections to fit your application. For specialty sizes, custom tracks can be manufactured.

Wire can be added on a wall greater than .120”. There is no maximum wall thickness. Wire can be added through multiple passes to match the wall thickness of any application. Keep in mind that higher schedules call for multiple passes, resulting in longer weld times.

Orbital Welding Process

Before you start an arc, there are several important steps to make sure the piece is ready for the weld.

Step 1. Cut

Before aligning tube or pipe ends, they first need to be cut. Orbital saws rotate evenly around the piece, creating a clean and even cut. This is commonly used on sanitary tubing and small thin-walled pipe.

For larger applications, use a clamshell to cut (and even bevel) through large pipe. A sturdy blade will part even the toughest pipe to get it ready for welds.

If you do not have a clamshell, a band saw can be used.

Step 2. Face or Bevel

Tube and thin-walled pipe: After cutting, use a tube facing tool to get rid of burrs and other imperfections. Though it is often overlooked, creating a perfect alignment is an important part of creating a good weld, in both orbital and hand welding. Burrs in welds can create a space for bacteria to build and contaminate in the future.

Pipe: Use a portable pipe beveling tool before orbital pipe welding. A bevel is needed to create full penetration on heavy walled pipe. Though there are several types of bevels, a “J-prep” is one of the most common for this type of automated welding. Filler wire is later added during the weld to make up for the missing material.

Step 3. Clean

This step is extremely important, especially in sanitary welding stainless steel. Cleaning the tube or pipe gets rid of potential contaminants and puts you in the best position for a successful weld.

Step 4. Tungsten

To strike an arc, you'll need an electrode. In this case, it will be ceriated tungsten. The size and length depend on your application – O.D. sizes and wall thickness are a few of the factors to consider. The number of welds per piece of tungsten depends on the quality of the tungsten as well as the material and O.D. of the workpiece.

Read more about choosing and changing tungsten electrodes.

Once you have the appropriate piece, place it within the weld head in the tungsten holder.

Step 5. Align

In orbital fusion welding, the fit-up is extremely important when it comes to the penetration of the weld. Place the two ends together inside the weld head, ensuring they are lined up with the tungsten electrode. Then, simply clamp both sides down.

If you are welding with filler wire, you will need to tack the two pieces together or use a clamping device to put the two ends together. Then, the weld head will need to be aligned with the joint. The tungsten, wire angle, and wire distance can be adjusted as needed with the remote pendant.

Step 6. Purge

After aligning, purge oxygen from the inside of the tube or pipe, using argon or mixed shielding gas. If you try to perform a weld without purging, the oxygen present will cause discoloration and imperfections greatly impacting the integrity of the weld. Purging also helps keep the weld from sinking in during wire-add applications by maintaining pressure on the inside of the pipe.

Use purge plugs, back purge wands, or purge trees to diffuse the chosen inert gas evenly into the tube or pipe. Basic purging can be done with heat-resistant tape, but you sacrifice the consistency provided by purge plugs. With your workpiece purged of all traces of oxygen, you are ready to start an arc.

STEP 7. Program

Today’s power supplies feature auto-programming technology. It is as simple as entering the weld head being used, material being welded, O.D. size, and wall thickness into the power supply. The power supply will then generate a pre-developed program. Often very little adjustment will need to produce an accurate weld program. Otherwise, the operator will need to program the following to develop a program:

- 4 or more welding levels (must include enough time for tie-in before the downslope)

- Control welding speed

- Adjust amperage to get uniform, fully penetrated welds

To fully understand programming needs, schedule orbital welding training. You will get in-depth details and hands-on experience while learning from an orbital welding expert.

Step 8. Weld

With all these steps completed, you are ready to strike an arc. The tungsten will then rotate 360 degrees around the workpiece to create a uniform weld.

We recommend testing an initial weld and making adjustments to the welding parameters as needed for your application.

Orbital Welding Supplies

To operate your orbital welding equipment successfully, you must have the proper supplies and accessories. As mentioned earlier, the most necessary accessory in orbital welding is a tig welding electrode - ceriated tungsten. Tungsten is needed to start an arc for the weld.

Other essential orbital welding supplies include:

- Cleaning Supplies

- Inert Gas & Dual Regulator

- Weld Head Bench Mount

- Oxygen Analyzer

- Printer Paper

- Purge Plugs

Orbital Welding Training

To achieve consistent and repeatable welds, it is recommended that you receive training before operating an orbital welder. Training sessions ensure confidence in your orbital welding equipment and your ability to operate it. Off-site or in our fully equipped weld lab, Morgan Industrial Technology offers an organized, accommodating, and comfortable environment built for constructive learning. Training for orbital tube welding typically takes 1 day while orbital pipe training takes 3-5 days depending on the application.

Equipment Repair

To avoid equipment errors and breakdowns, take preventative maintenance measures such as cleaning your weld head rotor and sending in your equipment for annual calibration. If your equipment does go down on a job, send it to a factory-certified repair center such as MIT. Our team has the knowledge and resources to help you evaluate your specialty application and determine the necessary components.

Contact Morgan Industrial Technology to find out if an orbital welding machine is right for your application. MIT represents the best manufacturers in the industry and is your single source for orbital welding equipment, repairs, rental, and training.

Tags:

Orbital Weld Heads, Orbital Pipe Welding, Orbital Tube Welding, Orbital Welding Supplies, Orbital Welder, Orbital WeldingDec 3, 2021 9:05:55 AM

.png)

Comments